Shenzhen SunTex has a team of production and assembly staff who work together with sincerity. They are responsible for the welding of all product parts, product assembly, testing and final packaging. Every production step and every production link is strictly controlled.

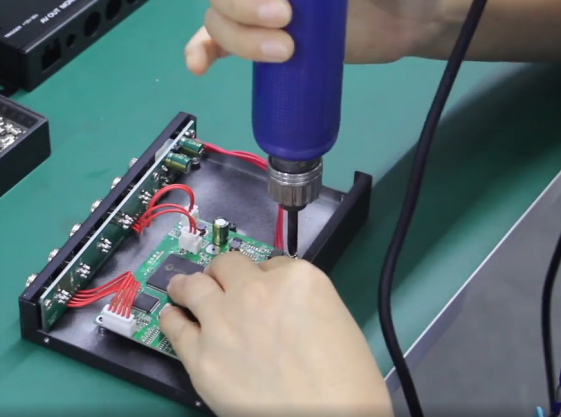

1.Soldering of parts. Professional welders solder the parts of the motherboard.

2.Assembly of PCB main board and product casing.

3.Product upgrades and testing. After the software development team finalizes the software version and the main body of the MDVR is assembled, the production and assembly team will also upgrade and function test the product. The assembled hardware device is integrated with the software system for functional testing and performance debugging to ensure the stability and reliability of the MDVR.

4.Quality Inspection. Quality inspectors will carry out strict quality checks on products that have been manufactured. This includes functional testing and appearance inspection to ensure that each product meets the standards for shipment.

5.Packing session. Finally, there is the packaging session of the products. Each product is packed in special boxes. Finally, according to the customer’s requirements, labeling and so on.